Advanced Manufacturing Facility

Boscon’s manufacturing facility is equipped with the highly-advanced “Automatic Spun Pile Production Technology”, capable of producing 80,000 meters if PHC spun pile per month. The manufactured piles come in various types, all are customizable to different size, ranging from diameter 300mm to 600mm with standard lengths varying from 6m to 15m in single pieces.

Boscon equip with the most sophisticated machinery available to the market:

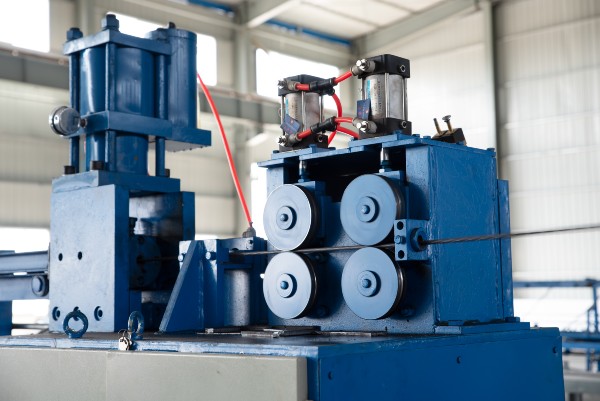

- Hight precision steel bar cutting machine

- Medium temperature heading machine

- Full automation concrete batching

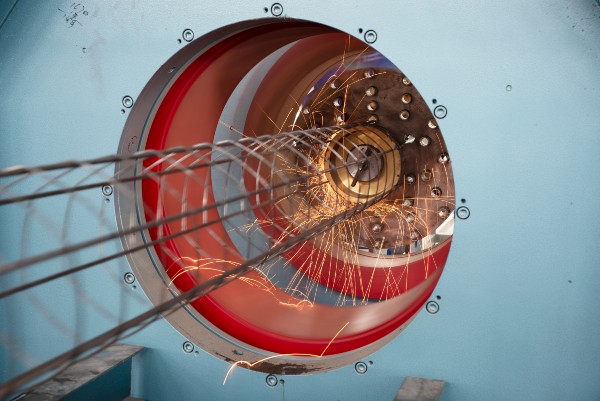

- Spinning machine

- Cage welding machine

- Boiler

- Advanced laboratory accessories

Automation In Spun Pile Production

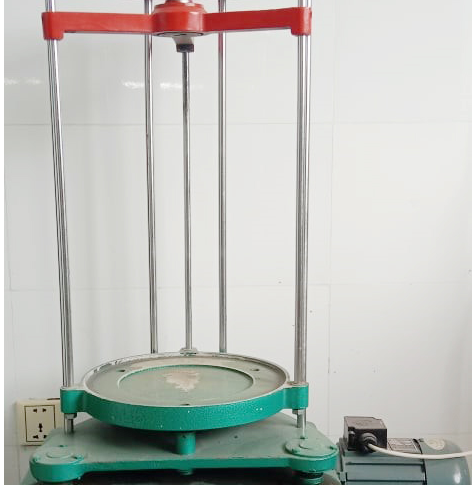

Advanced Laboratory Accessaries

Quality Control

Quality Control of all materials and components in pile manufacturing is an essential part of our production process. Regular testing is carried out to ensure quality, durability, and performance of the pile products.

Among the many test carried out are:

- Test on concrete cubes for compressive strength

- Checks on finished piles for straightness, cross-section, alignment of joint and fittings

- Slump test on concrete batches

- Test on aggregate samples for grading and slit content

- Stringent checks on reinforcement cages for steel quality, spacing, and stirrups pitch