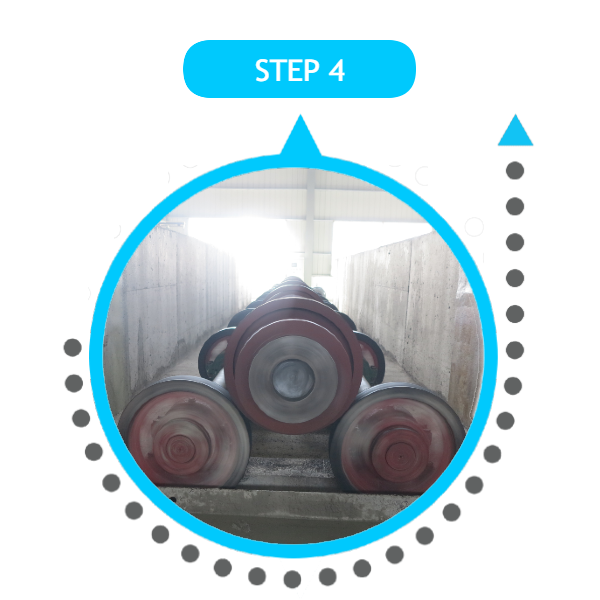

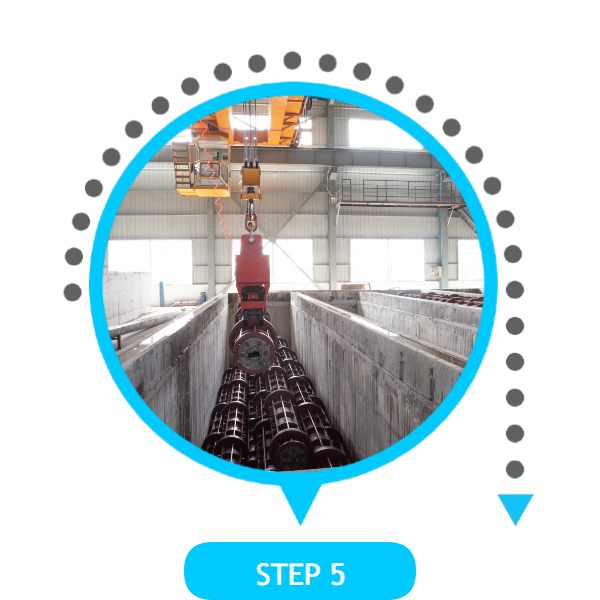

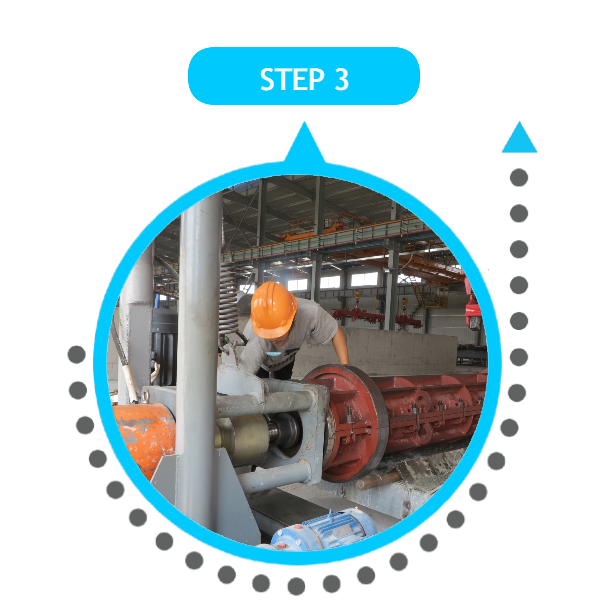

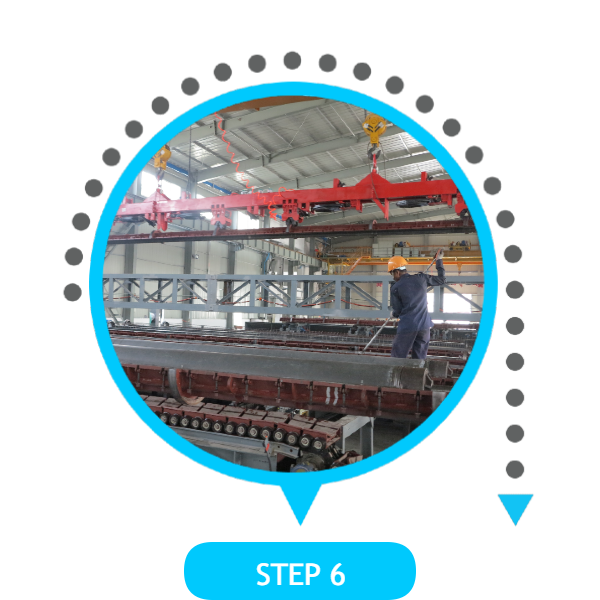

Production Process

Product features and advantages

Pre-Tensioned Spun High Streng Concrete Pile or PHC is the high strength spun pile with the conrete compressive strength of about 80Mps.

It is circular in cross-section and are manufacutured in sizes ranging from diameter 300mm to 600mm with standard lengths varying from 6m to 15m in single pieces.

The pile is made by spinning cylindrical molds filled with fresh concrete, therefore the produced piles could be very compact. Unlike pile types, PHC pile requires less concrete and therefore very economical.

PHC pile is designed to bear various types of structure and environment conditions. It is used among others on High-Rise Buildings, Hotel, Condo, Super Market, University, Villar, Borey, Commercial Building, Industrial Buildings, Marine Structures and Bridges etc.

Benefits of PHC Piles:

- High loading capacity

- Excellent anticorrosion performance

- Strong resistance to bending

- Construction period can be shortened

- Construction expenses can be saved

Property of PHC Pile JIS A 5373-2010

| Outside Diameter D(mm) |

Thickness T(mm) | Types | Standard Bending Moment (N=0) |

PC Bar Diameter (mm) |

Number of PC Ba |

Section Area Ac (cm2) |

Equivalent Sectional Area Ae (cm2) |

Moment of Inertia of Equivalent Section Le (cm4) |

Section Modulus Ze (cm3) |

Weight (kg/m) |

Installation Load(Ton) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cracking Mcr kN m |

Break Mu kN m |

|||||||||||

| 300 | 60 | A | 24.5 | 37.2 | 7.1 | 6 | 450 | 452 | 35,160 | 2,364 | 120 | 150 |

| 350 | 65 | A | 34.3 | 52 | 7.1 | 7 | 579 | 582 | 63,570 | 3,633 | 155 | 200 |

| 400 | 70 | A | 54 | 81.4 | 7.1 | 10 | 721 | 725 | 105,900 | 5,296 | 190 | 250 |

| 400 | 80 | A | 54 | 81.4 | 7.1 | 10 | 800 | 804 | 111,900 | 5,596 | 210 | 280 |

| 500 | 90 | A | 103 | 155 | 7.1 | 14 | 1,154 | 1,159 | 261,100 | 10,450 | 310 | 400 |

| 600 | 100 | A | 166.8 | 250.2 | 7.1 | 18 | 1,564 | 1,571 | 521,600 | 17,390 | 420 | 550 |

Property of PHC Pile GB 13476-2009

| Outside Diameter D(mm) |

Thickness T(mm) | Types | Standard Bending Moment (N=0) |

PC Bar Diameter (mm) |

Number of PC Ba |

Section Area Ac (cm2) |

Equivalent Sectional Area Ae (cm2) |

Moment of Inertia of Equivalent Section Le (cm4) |

Section Modulus Ze (cm3) |

Weight (kg/m) |

Installation Load(Ton) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cracking Mcr kN m |

Break Mu kN m |

|||||||||||

| 400 | 95 | A | 54 | 81 | 9.0 | 7 | 906 | 910 | 123,000 | 3,075 | 241 | 310 |

| 400 | 95 | AB | 64 | 106 | 10.7 | 7 | 904 | 909 | 123,050 | 3,076 | 242 | 300 |

| 500 | 100 | A | 103 | 155 | 9.0 | 11 | 1249 | 1257 | 285,000 | 11,400 | 333 | 430 |

| 500 | 100 | AB | 125 | 210 | 10.7 | 11 | 1240 | 1250 | 284,950 | 11,430 | 335 | 420 |

| 600 | 110 | A | 167 | 250 | 9.0 | 14 | 1686 | 1693 | 573,00 | 19,100 | 449 | 590 |

| 600 | 110 | AB | 206 | 346 | 10.7 | 14 | 1900 | 1905 | 573,050 | 19,050 | 455 | 580 |